Paying attention to increasing the lifespan of industrial brushes is one of the most important factors in the production of these products.

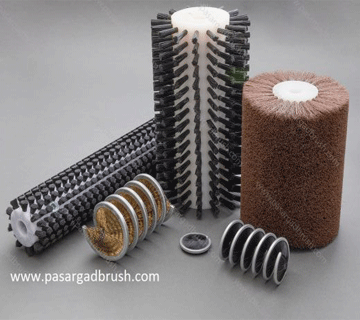

Industrial brushes are tools consisting of wire, nylon and animal hair threads that have different uses.

These brushes are produced in different types, each of which has a different use than the other. Types of industrial brushes are: Cylindrical, cylindrical or roller brushes, disc brushes, flat brush, strip brush (underdoor, sealant), belt, rotary, etc.

Important points in preparing and using all kinds of industrial brushes to increase their lifespan

– Paying attention to the strength and quality raw materials used in the brushes;

– Correct use of the brush according to the density of the fibers and materials used in it;

– Using the brush according to its task.

Pasargad Industrial Brush Company is trying to supply a quality product to the country’s artisans in line with the production and supply of the best industrial brushes.

To achieve this, the company pays attention to key points before producing and selling its products, some of which are:

- The customer must report a summary of brush performance to the experts of Pasargad Industrial Brush Company before producing the custom product;

- The company’s experts produce customized products using the best materials;

- Attention to the density of the brushes is considered by the manufacturers according to their application;

- Increasing the production efficiency and increasing the life of the brush is one of the important things in the production of Pasargad Industrial Brush Company products;

- Paying attention to the correct selection of the brush cycle, if you do not pay attention to this issue, serious damage will be done to the brush fibers;

- attention to the quality and number of fibers used in the brushes for their longer life; It should be said that brushes that are poor in terms of quality and number of fibers used in them will wear out sooner;

- adjusting the height of the brush from the work surface, which sometimes reduces the life of the brush by a fifth if the side surface of the fibers engages with the other surface of the work instead of its end;

- Keeping the brushes in the right place after production and while waiting for delivery to the customer;

- Proper packaging at the time of sending the products to prevent bending and breakage of the fibers of the brushes, which will also increase the lifespan of the brushes.

The advice of the experts of Pasargad Industrial Brush Company to craftsmen is to clean them well for the next use after using all kinds of brushes, especially cleaning brushes.

One of the advantages of regular brush cleaning is reducing the costs of replacing them and increasing the lifespan of the brushes.

It should be noted that one of the things that reduce the lifespan of industrial brushes is washing them with acid or other chemicals.

If any of the artisans face problems due to washing their brushes with acidic and chemical substances, they can contact the experts of Pasargad Industrial Brush Company and use their valuable experience in this regard.

The experts of Pasargad Industrial Brush Company produce and supply their products according to the opinions and orders of the artisans, considering all the important issues in the production of industrial brushes and trying to increase the lifespan of industrial brushes as much as possible.

Our effort is to satisfy you.

بدون دیدگاه