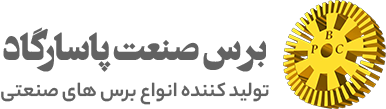

Sanding Brush

The use of polishers is very common in MDF or vacuum cabinets. Due to the fact that the use of drillhead sanding in these cases results in a smooth and polished surface of wood in different types, whether vacuum or MDF.

Sanding wood is very important because it is one of the basic steps. Contrary to the simple appearance of its name, this is not an easy task and requires a skilled craftsman. Because after finishing the work, the wood of the product must be perfectly polished. As a result, the wood surface begins to be vacuuming and doing MDF.

A wood sanding brush is a type of brush that is used after sanding to remove out-of-reach areas. This type of polisher is produced according to the needs of customers in different shapes and sizes, including discus headband and strip brushes.

PBC wood polisher has been able to satisfy its customers in the wood and MDF industries.

Because this product has been able to increase the working time of workers to one-tenth compared to manual methods. In addition, this industrial brush is of great importance in terms of quality of work and in terms of saving on polishing costs.

The workload of this product is such that it has been able to polish more than twenty MDF units. Therefore, considering this amount, this industrial brush can have a high economic justification for customers. It is noteworthy that the wooden parts or MDF parts polished by this tool after painting, cover pressing, or vacuum coating cover will cause the least possible waste and prevent customer dissatisfaction for the customeres.

The working dimensions of this sandpaper are 55 mm in length and 150 mm in diameter with a 10 mm trail has been introduced into market.

The materials used in PBC’s headdrill sandpaper are usually made from German Aquaco and sisel yarns sandpaper, or Mexican plant fibers or hemp (American turf), and polyethylene or aluminum base.

These products are also produced from 120 to 600 grades.

Features of this type of brush include:

- This sanding brush is for wood industry.

- Frequent use of the base of this brush and easy replacement and, speedy head changing are its outstanding features.

- It has the necessary durability for the manual electric motor speed.

- It is very easy to use.

- It has high cleaning and high linting power as well as permeability in the depressions on the surface of treated wood and MDF.

- Balance of the polishing set

This brush with a praiseworthy quality is made in the best and PBC as the largest brush factory in Iran, which has a very clear ability to polish all kinds of irregular and rough surfaces, as well as kitchen cabinets, doors, windows, furniture, and etc., with customers satisfactory.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.