Solar Panel Washing Brush

Brushes can be widely used in any industry and profession depending on the type of consumption. From surface abrasion to refining and cleaning various surfaces and industrial equipment!

But also to be known that the quality of brushes is in the first place that should be considered. For your convenience, we suggest that you prioritize the PBC as a guarantor to advance your goals.

As we mentioned, brushes are used in various fields, including solar panels, which we will explain to you below. Join us:

What is a solar panel?

The solar panel is made of semiconductor compounds whose main function is to convert sunlight into electrical energy.

Solar panels or solar panels play a very important role in saving energy. In Iran, it is also used behind houses, companies, etc. to reduce energy.

Solar panels absorb dust and other wastes over time, reducing their energy efficiency. Therefore, removing dirt and periodically cleaning these panels is very important and should be given a lot of attention. This is done by washing the solar panel.

The solar panel farm is established in arid and semi-arid areas where sunlight is higher than in the north part of Iran. In desert areas and in the south of Iran, due to weather conditions and the presence of dust, as well as local dust, the pollution of solar panels has become one of the biggest problems for farmers. This is because if the panels are not washed in time, dust and dust sitting on the cells can sometimes disrupt more than seventy percent of the farm’s electricity generation. As a result, this could lead to a sharp drop in solar power plant efficiency.

In this regard, PBC has been able to market the industrial brush suitable for this industry with the best materials, the most prominent feature of which is its high cleaning power and high durability in adverse environmental conditions of these farms.

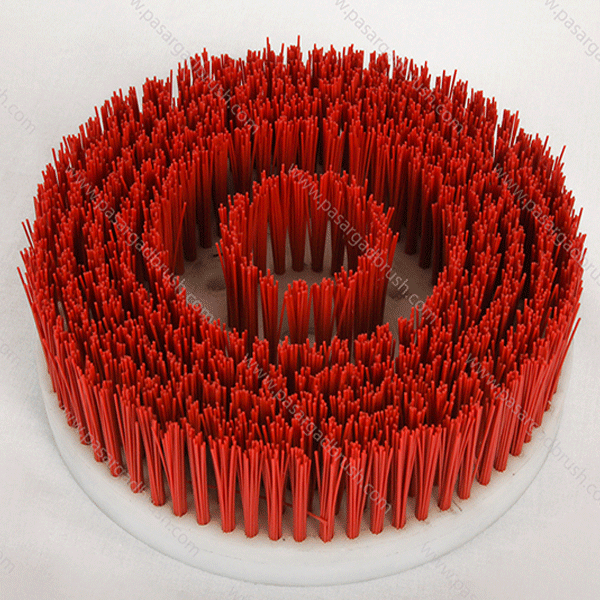

The most important features of the solar panel washing brush are as follows:

High resistance of fibers used in this brush against the scorching sun

Ability to bear the weight of the brush by the cell due to the work limitations on these cells, the mono filaments used are produced from the low density of the selection

Using of the base in the washing brushes of these panelswhich is usually from the group of strips and low density polymer materials

Ability to work brushes in water washing and drying

Easy to install on the washing machine

The following types of solar panel brushes are as follows:

Brushes are produced in different types such as disc, cylindrical brush, cylinder strip, spiral cylinder, zigzag cylinder, parallel cylinder, and chess cylinder.

The design and production of brushes in relation to similar foreign products in one piece and in any length and perfume at a reasonable price and high quality is produced and supplied by PBC.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.