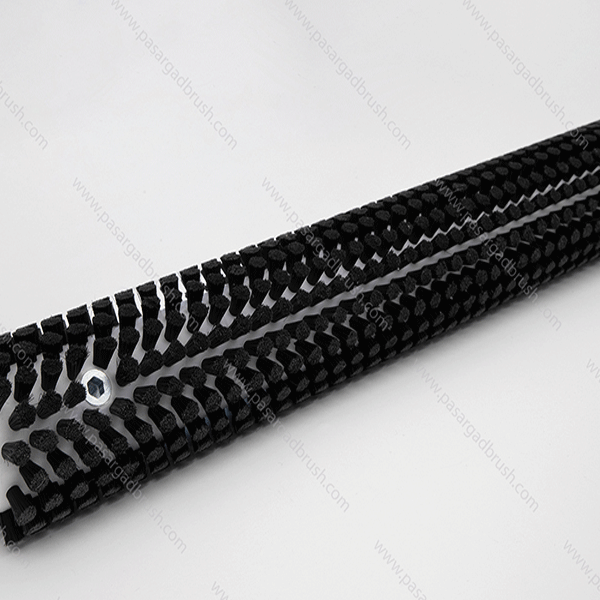

Stone-Cutting Brush

What kind of brushes are used in the stone-cutting profession?

The stone-cutting industry in Iran is divided into two categories. In the first type, the consumption of stone-cutting products is limited to the interior.

And in the second type, stone-cutting has equipped machines which is active in the field of export. In this industry, with the help of brushes, designers can cleverly add to their creativity and make their products more attractive. For this reason, choosing the right set of brushes is essential for the stone industry.

The use of masonry brushes helps you to show a more beautiful effect of the stone’s natural texture.

Produced brushed by PBC with considerable efficiency, these brushes can give a good effect to the stones. These brushes can also be used for white marble and travertine stones. Stone-cutting machines are more common in newly established factories than in industrial brushes. Because the lack of brushes in the old stone-cutting industries has been very evident. For this reason, in the mechanism of new machines in this industry, cylindrical brushes and disc brushes are used. These brushes save a lot of water. As a result, PBC has been able to gain a clear position in the production of this type of brush.

The brushes used in the stone-cutting industry are usually made of polymeric filaments and sometimes of natural bristle (ponytails and horse’s mane) as well as hemp or vegetable fibers.

One of the largest manufacturers of brush and industrial brushes is PBC. The brushes produced by this company can be used in a variety of production line polishing equipment, stone- cutting machine, stone cleaning machine, manual polishing machines as well as manual stone polishing machine.

These brushes can be used for marble, granite, natural stone, sandstone, and tile. These brushes can be made of nylon or high purity silicon carbide, too.

The brushes used in the Patinato of various stones are usually abrasive brushes. A wide range of abrasive brushes ensures a good effect on stone surfaces.

High brush density and quality of consumables provide lower production costs in favor of the user. The density of the brush may vary depending on the hardness of the stone used.

PBC’s extensive technology, combined with long experience in the brush production industry, allows us to design and manufacture customized brushes to suit the customer’s needs in addition to the standard brush in our production area.

Other Industrial Wire Brushes in the Stone-Cutting Industry:

Wired brush is another type of industrial brush that is in the group of harsh and rough brushes due to its intertwined wires. It can be used in work such as surface scaling, staining, smoothing rough surfaces of all types of rocks, drying of smooth surfaces before painting and so on. This type of brush can be installed on the axis of fixed or moving machines.

The use of wired brush is as follows:

- To smooth and polish hard surfaces such as rocks and metals, as well as in other industries such as shipbuilding.

- Use in auto manufacturing and construction

- It is used to remove rust on surfaces and to pay for all kinds of metals, steels, irons, and stones.

The material filaments of these brushes are usually made of hard steel with a high percentage of carbon alloy.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.