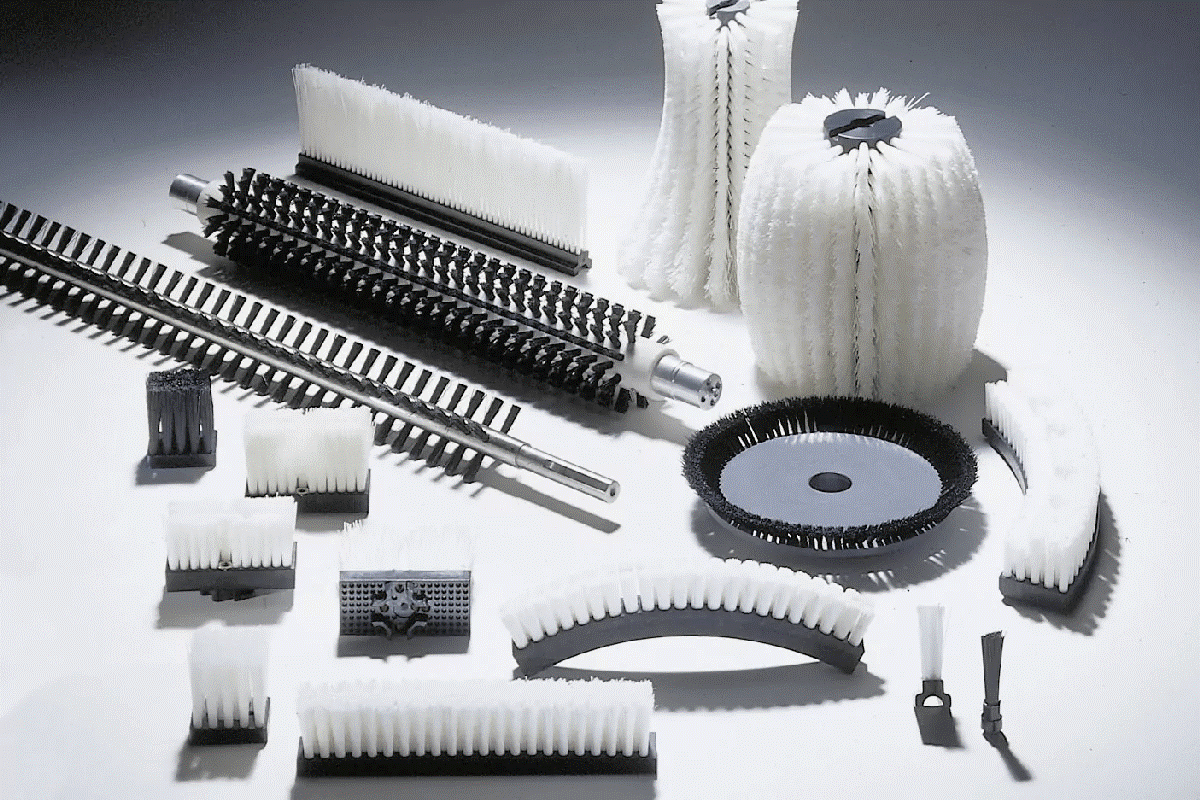

One of the tools that is highly used in cleaning factories and different places is an industrial brush. The production of various types of industrial brushes is done according to the application and how to use them in different places. In general, industrial brushes are different from each other in terms of user and usage, form, handle or body and type of brush.

In this article, we are going to examine the types of industrial brushes and how to make them. If you also intend to increase your knowledge to buy the best industrial brush or if you are interested in how to make all kinds of industrial brushes, stay with us.

What is an industrial brush and in what areas is it used?

Industrial brushes are among the tools used in industrial scrubbers. Scrubbers or industrial floor cleaners are used to clean the floors of all types of industrial and non-industrial environments and have been greatly appreciated due to the simplicity of working with them. The industrial brush is placed behind this device and causes the floor to move forward and thus wash the floor.

However, industrial brushes have more applications and are used in different sectors. One of the main uses of industrial brush is its use in textile and fabric industries. The way industrial brushes are made makes certain types of them work very well in removing lint and smoothing fabric folds, and have other uses in removing dust, combing under cutting, increasing fabric strength, etc.

Other uses of industrial brush include its use in steel industry. The brushes that are used in steel production factories, due to their high temperature resistance and strength, can remove the grease created on the galvanized sheets and can wash them at a high speed.

In addition to these cases, industrial brushes are widely used in other sectors such as pharmaceuticals and industry and mining. These brushes can be used to separate and create rows of different medicines, clean and clear pills and capsules, equalize iron sheets and width of wood, etc.

Different types of industrial brushes

How to make different types of industrial brushes?

In the past, the production of industrial brushes brought many difficulties and problems. The main reason was the lack of technology and equipment necessary for the rapid production of this tool. The decrease in the production of industrial brushes caused an increase in their import to the country, which led to an increase in price and in some cases, a decrease in their quality. But today, with the increase of knowledge and technology, as well as the use of various industrial devices, the manufacturing and production of industrial brushes, with the best quality, is being done in different cities of Iran.

The most important production centers of industrial brushes in Iran are located in the cities of Shiraz, Tehran, Isfahan, Mashhad and Tabriz. The way of making different types of industrial brushes may be different according to the type of brush and its applications, but the general method of making them is the same and the general method of working is the same. The steps of making different types of industrial brushes are as follows.

- Designing the type of brush and determining its sizes

- Production of brush body and handle

- Making multiple holes in the brush handle

- Tuft of filament roots in the piercing part of the handle

- Brush leveling

How to make all kinds of industrial brushes

The way to make all kinds of industrial brushes and its production steps is in this way that the initial shape, dimensions and sizes of the brush are determined and designed. In the next step, the main body or the heel of the brush is made by industrial machines.

Depending on the type of brush, this body can be made of different materials; For example, light and compact materials such as Teflon, ABS, PVC and polyamide are used in making the body of round brushes. The body of the door brush is also often made of anodized aluminum profile. This type of brush is very useful in preventing the entry of dust, vermin and also to prevent energy loss.

In the next step, regular holes are made on the surface of the body, with a predetermined density, and the filaments of the brush are inserted into them by industrial machines. In the final stage, the operation of equalizing and leveling the froche strands will be done and the industrial froche is ready to be packaged and supplied to the market.

Fibers used in making all kinds of industrial brushes

As mentioned, the body of industrial brushes can be made of different materials according to the type of application. Another part of this tool that has a direct connection with the surface is the fibers and threads of the brush. Nowadays, the production of these strings is done with industrial devices and in a short period of time.

The types of fibers used in industrial brushes are divided into natural and artificial, each of which has a separate application. Natural fibers are made from vegetable fibers, animal hair such as horses, cows, etc., as well as palm fibers. The synthetic fibers used in industrial brushes are mostly nylon threads, wire and metal threads, etc.

How to buy and price all kinds of industrial brushes

How to make all kinds of industrial brushes will have a direct effect on the pricing of these products. The different reasons that cause the price difference of these products include the size of the brush, the type of threads and the thickness of the filament used, the body material, the production method and the type of the brush.

Buying different types of brushes and industrial brushes directly from the brush factory is a great advantage. If you intend to buy all kinds of brushes and industrial brushes, you can buy the product you want with good quality and price by viewing.

Conclusion

Industrial brushes have important applications in different sectors. These brushes are produced in different dimensions and models, each of which has a unique application and is used in various industrial, pharmaceutical, agricultural, etc. sectors. In this article, we examined how to make different types of industrial brushes as well as their different uses. If you intend to buy all kinds of brushes and industrial brushes with the best quality, you can contact the experts of Pasargad Sanat Brush Company.

بدون دیدگاه