Ceramic Tile Factories Brush

First, PBC invites visitors to read a part of the ceramic tile industry in the country:

Tile (Kashi) is a word derived from the city of Kashan and was famous in the early Islamic period as the center of pottery industry.

Tile is a piece of artificial stone that has different lengths and widths. Also, the thickness of the tile is a few millimeters, one side of which has a smooth and polished surface and glass.

Tile is a type of ceramic and pottery product that has many applications, especially in the construction industry. Therefore, the use of tiles in various uses is very important.

Its uses include the followings:

- Use in bathrooms

- Use in kitchens

- Use it in toilets

- Use in man wall toilet

- Public places

- Religious places

- Decorations inside and outside the building

- Sanitary facilities

- Use as a moisture insulator

also mentioned.

A piece of tile usually consists of two parts:

- Pottery piece: which includes a skeletal bone

- Glaze on the tile: which is glass material and is used as a coating on the tile

What are the types of tiles?

- Wall Tiles

- Floor Tiles

- Three-D Tile

- Porcelain Tiles

Tiles are very suitable for use in religious places, especially health and public places, due to their smooth and polished surface. Because it is very easy to clean and wash. And its surface can be easily cleaned of all kinds of contaminants and dust. To clean and wash the tile surface, there are brushes that can be counted on in these cases.

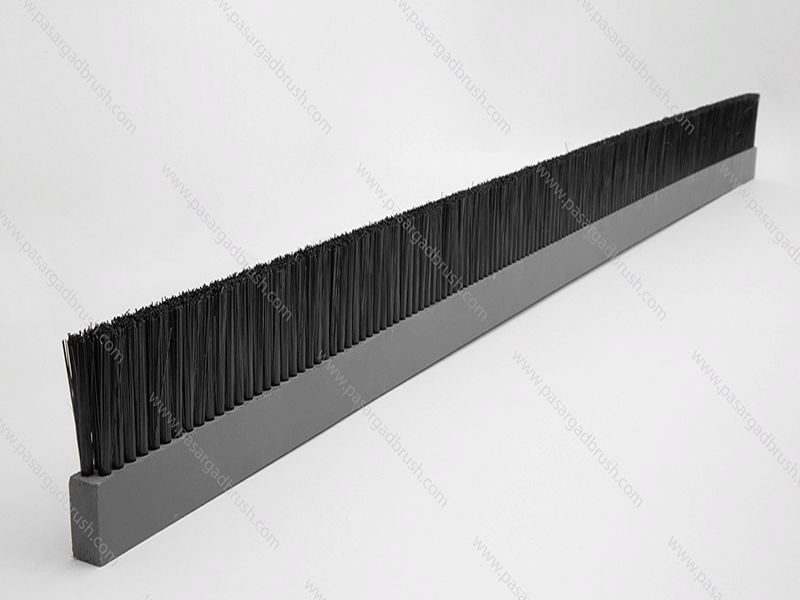

Ceramic tile industry brushes are a great option for removing any dirt on the tile surface and are easy to apply. It is noteworthy that this brush is produced and distributed by PBC with the best quality and the best available materials.

Ceramic tile industry is a type of industrial brush whose main task is to remove dust and clean all kinds of ceramic tile surfaces.

The brush of ceramic tile industry is produced from the best and highest quality materials available in the market and according to the needs of factories producing all kinds of ceramic tiles.

This type of brush has different types and has a lot of variety.

Here are some of these brushes:

- Rotary Brush

Rotary brushes are usually placed side by side and sequentially. As a result, they become a series of cylindrical brushes. These brushes are usually connected to each other by direct connection couplings. The ingredients of these brushes are polypropylene and polyester, which also has a high cleaning property

- Dics Brush

A disc brush is a type of industrial brush which is applied after pressing and drilling. In this section, all of its tasks and technical specifications are exactly the same as the more routine brushes.

The disc brushes used in the tile sorting unit are used for polishing or glossing the product. That is why the fibers used in this product are a kind of animal bristle that has high wax absorption and shine.

- Belt Brush

Belt brushes are usually mounted on the press line. This type of brush is produced on thermal polyurethane belts from 200-micron to 500-micron polyamide threads.

- Tape Brush

Tape brushes are usually produced between 1 and 2 meters. This type of brush is commonly used as a supplement to rotary brushes in the press unit. Due to the working position of this type of brush, polyester monofilaments are used in the twisted of these strip brushes or alarms.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.