Metal Mining Brush

Another special product of PBC is the metal industry mining brush, which has numerous applications in the mining industry. The properties and uses of this type of brush are as follows, we invite you to read more:

A metal mine is a place where iron ore and various metals are extracted and produced. In this industry, industrial equipments and machineries are used to carry out light and heavy operations, and the brush is not ineffective in advancing such mining development performances.

There are several types of brushes available in this industry, and we will cover just a few of them:

- A type of brush which is used in this industry can be made of carbon steel, stainless carbon steel, brass or nylon, stainless steel. This type of brush has high-density fibers and its applications include cleaning soot and carbon residual and deposits and all kinds of contaminants in metal pipes.

- Another study used in this industry is suitable as a cleaner for larger surfaces for non-ferrous and soft metals. This type of brush is made for use in wireless power tools, and using it, the battery of your wireless tools may last up to 30% longer than when using an ordinary brush of the same type. There are other wire brushes that can greatly prevent surface damages. The same sensitive surfaces include metal sheets, furniture, or glass panels, thin aluminum sheets, and so on.

- This type of brush works in such a way that it works like a brake by angling the bristles so that no damage is done to the surfaces while removing contaminants from the work surface.

- These types of brushes are produced in different designs and sizes depending on the type of consumption.

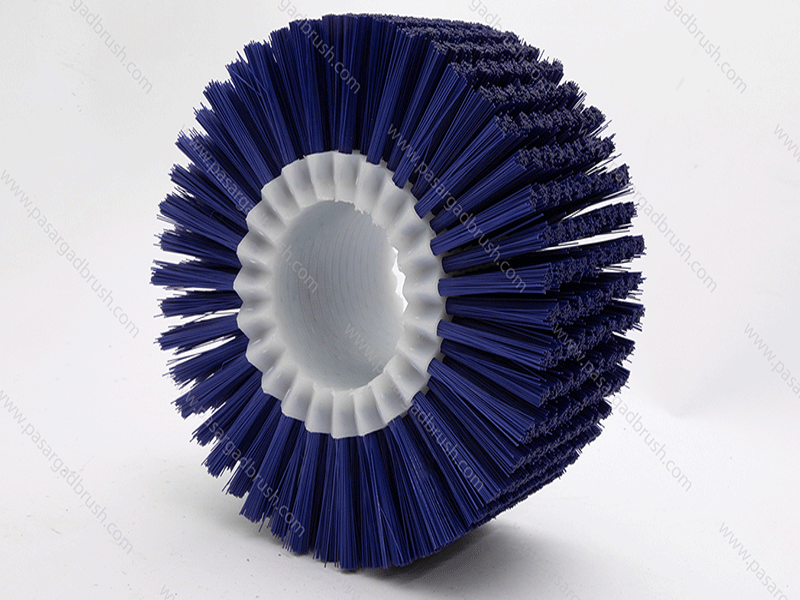

- Another type of brush produced by PBC, which ultimately produces quality and efficiency, is called a disc brush. Disk brushes are designed and manufactured for specific applications that require the formation of a specific piece and diameter in the construction of the urethane composite base. This brush can be easily installed on automatic machines, custom designed equipment, CNC machining centers and robotic centers.

- The brush has numerous uses that can work best in any context, including trash removing, surface preparation before any operation, and cleaning after finishing work, removal of rust, any radii created by the edge.Metal mining brushes are usually made of polymer cylinders made of polyamide (perlon) or polypropylene and wired cylinders, which are mostly made of stainless steel. One of the most sensitive brushes in the metal mining industry is called belt filter brush. This type of product, due to its high dimensions and unique design, PBC has been able to eliminate this industry from the import of European countries.

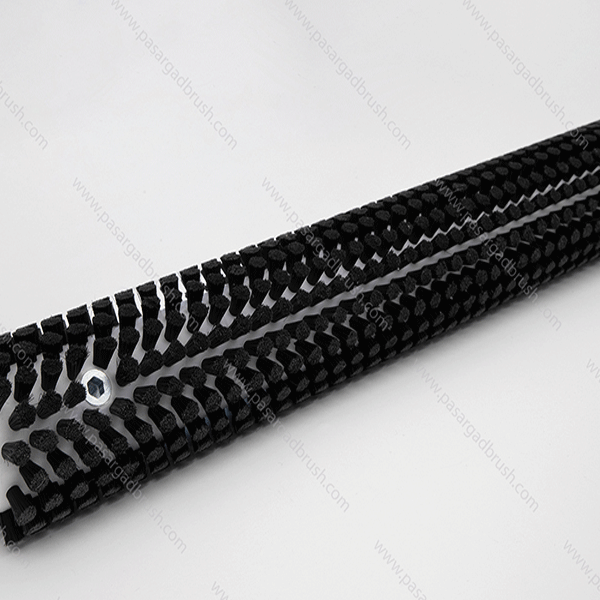

- Another product that is used in this industry is cleaner belt brushes, which are widely used in various conveyors and are used to clean conveyor belts.

- The best design for belt cleaners is zigzig cylindrical brushes, which, due to their special shape, can also have a very good effect on attached objects to the conveyor. Another brush used in this industry is stainless-steel wire brush, which is widely used for cleaning and washing copper cathodes, and PBC has been able to provide this industry well.

Another use of the brush in the mining industry is its use big segment taking machines. It is used to determine the thickness and uniformity of wood timber or iron sheets. The metal mining brushes are offered to you in different types and dimensions by PBC. Feel free to leave us your needs. Quality is the guarantee that PBC will give the customers. We are waiting for you.

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.