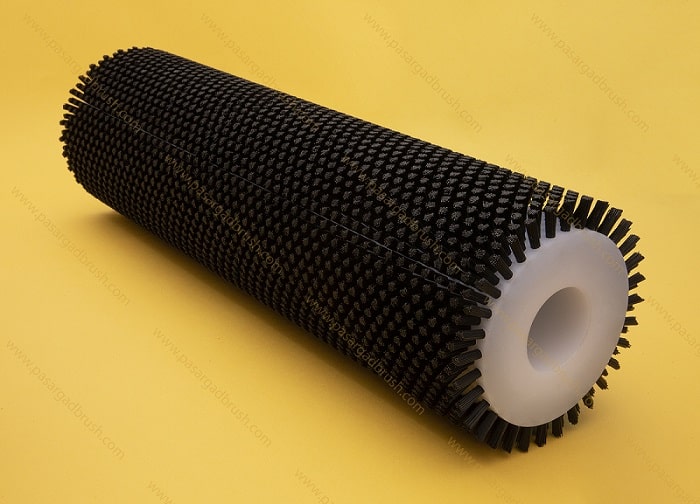

Hoich Shui brush is one of the main brushes produced by Pasargad Industrial Brush Company with the best quality and different lengths and diameters. One of the reasons for the mass production of carrot washing brushes is their widespread use in carrot washing machines, because the competition between fruit and vegetable sellers, as well as the growing need of fruit and food supply markets, to use washing machines is increasing.

Carrot salting machine is one of the machines that is widely used for preparing and washing carrots, packaging and final supply of this product, which is the main task of this carrot washing machine. The use of an industrial brush for salted carrots with good quality and long life, as well as considering the dimensions and materials used for its construction, is one of the points that should be taken into account, because carrots are very exposed to pollution and agricultural land due to environmental conditions. Dirt and mud are placed, so accuracy is very important in the operation of these types of brushes that are installed in the carrot washing machine.

The advantages of using cylindrical brushes for washing carrots can be mentioned as reducing water consumption, reducing energy consumption, increasing efficiency in the process of washing carrots and reducing possible costs.

This type of industrial brush produced by the Pasargad brush factory is made of the highest quality and best type of nylon thread. This type of brush is produced in two types: a simple segmented cylindrical brush and a gear-coupled cylindrical brush, which according to the device of each can have many such applications. Change or charge when necessary.

This type of brush can easily remove the dirt on the carrot skin without damaging the surface of the carrot skin. The nylon fibers of the carrot salting brushes make it possible to protect the surface of the carrot skin from being scarred in addition to the high precision in removing dirt, which will be a guarantee for the repeated use of this type of brush in consecutive years.

What parts does the automatic carrot cleaning machine consist of?

The carrot washing machine usually consists of a high pressure sprayer, a carrot washing brush, a frame and a motor.

High pressure sprayer

A high pressure sprayer is usually suspended above where the brush is placed and connected to a water pipe to direct the water. The basis of the spray is that while the carrot is being cleaned by the brush, water is also sprayed from this part so that the cleaning process can be performed with a higher quality.

Industrial carrot washing brush

The carrot brush is the most important and main part of the device, which removes all the impurities on the surface of the carrot through friction, because the brush can reach all the uneven parts of the carrot due to its flexible and strong fibers.

the frame

Because the carrot salting machine is exposed to water for a long time, it is more susceptible to corrosion and rust, so it is better that the body of the machine is made of stainless steel, this will increase the life of the machine.

Engine

The motor mainly increases the rotation power of the brush and improves the high pressure spray process. The motor is placed on the left side of the carrot washer and is hidden under the frame. Also, to make the device smoother and increase its efficiency, the bearing part of the device is covered with lubricating oils.

What factors affect the price of a carrot washing machine?

The price of carrot washing machines is mainly influenced by the number of sprinklers, carrot washing brush, the capacity of the machine and the material of the machine body.

Capacity

There are different models of carrot washing machines, each of which can have a different output according to its type. One of the factors that affect the capacity of the machine or the number of carrots output is the length of the brush. The longer the brush installed in the machine, the more carrots there are. can cover, therefore, it will have more output, this will be one of the reasons affecting the prices of the device in relation to each other.

The body material of the device

Due to the hot market, the competition of carrot salting machine manufacturers, the body material has a significant impact on the quality and price of this machine, and the best type of material used is stainless steel.

Brush density

Brush density is one of the things that is very effective on the price of the brush, because the density and technologies used by Pasargad Industrial Brush Factory in manufacturing industrial brushes are in the best possible condition and this causes the price to increase.

Conclusion

Sanat Pasargad brush manufacturing plant produces and supplies all kinds of industrial brushes needed in different industries, which can have different prices according to their applications and the type of material used in making industrial brushes.

بدون دیدگاه